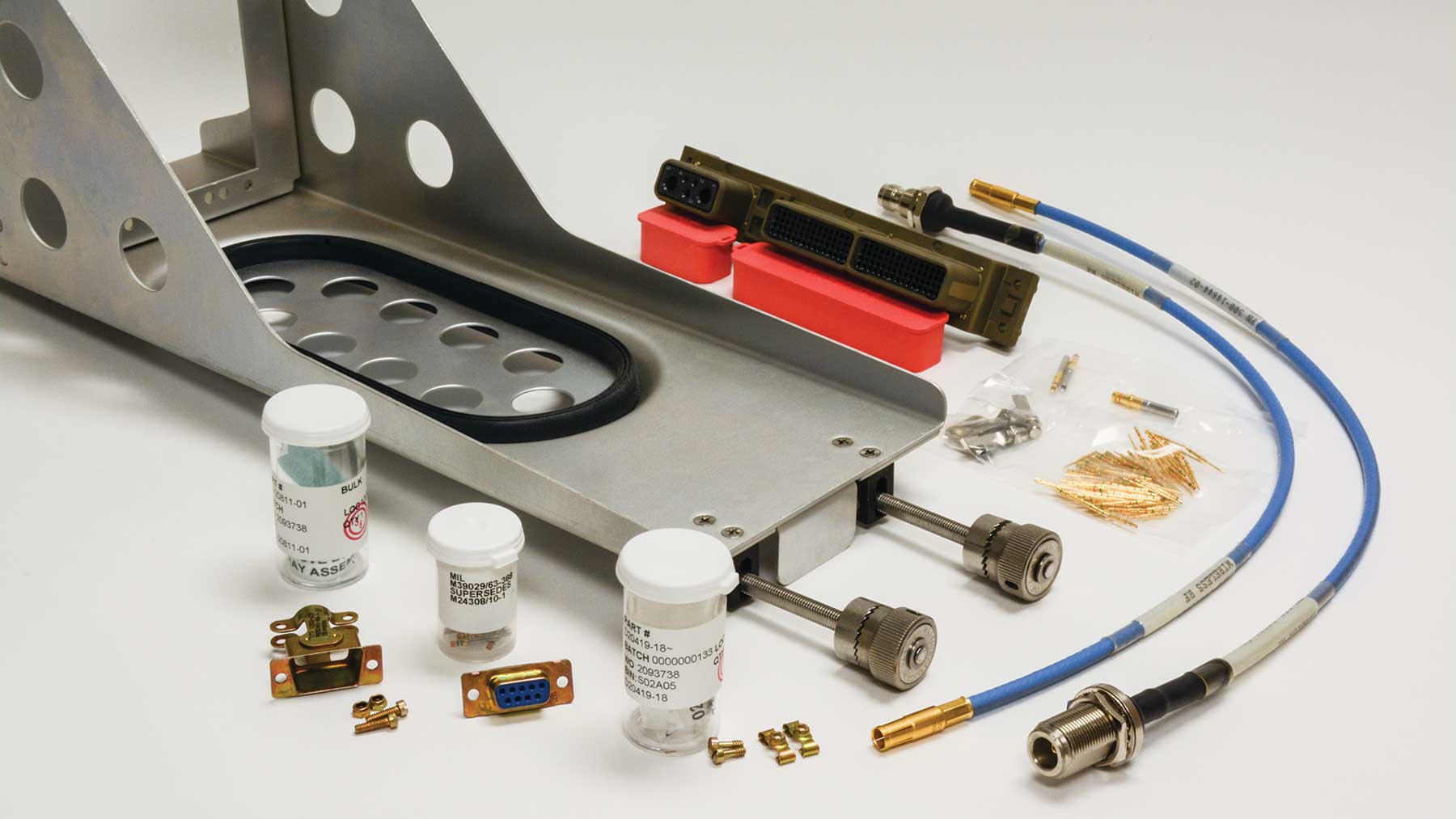

Aircraft Modification Kit Manufacturing

Spirit provides complete modification kit manufacturing and logistics services with complete parts traceability including:

- FAA–PMA Kit Manufacturing

- A & B Kit Manufacturing

- Laser Wire Marking

- Electrical Installation kits

- Mechanical Installation kits

- Full Parts Traceability

Spirit Aeronautics provides complete aircraft modification kitting services for aerospace Maintenance Repair Organizations (MRO) and military depot customers. Utilizing our Federal Aviation Administration certified Repair Station processes for aircraft parts fabrication and logistic services, we support our MRO & depot operations clients globally with our top-quality aircraft modification kits.

Our parts logistics team is routinely preassembling individual items into ready-to-ship kits as specified by our client or through our in-house engineering processes. We can utilize Engineering Orders, FAA Supplemental Type Certificates or our engineering department resources to develop and produce an appropriate Bill of Materials to provide kitting components.

Our highly skilled aircraft electricians build wire harness looms to all aerospace industry manufacturing standards. Our Sheetmetal fabrication artisans produce airframe modifications pieces, Special Missions stations and antenna installation hardware components in our well-equipped production shops. These skilled services add additional value to our kitting packages for MRO’s that do not have these highly specialized resources. Our team offers decades of aircraft modifications experience. We provide the deep Original Equipment Manufacturer service center authorizations as the critical resources needed to address major avionics or airframe modification projects.

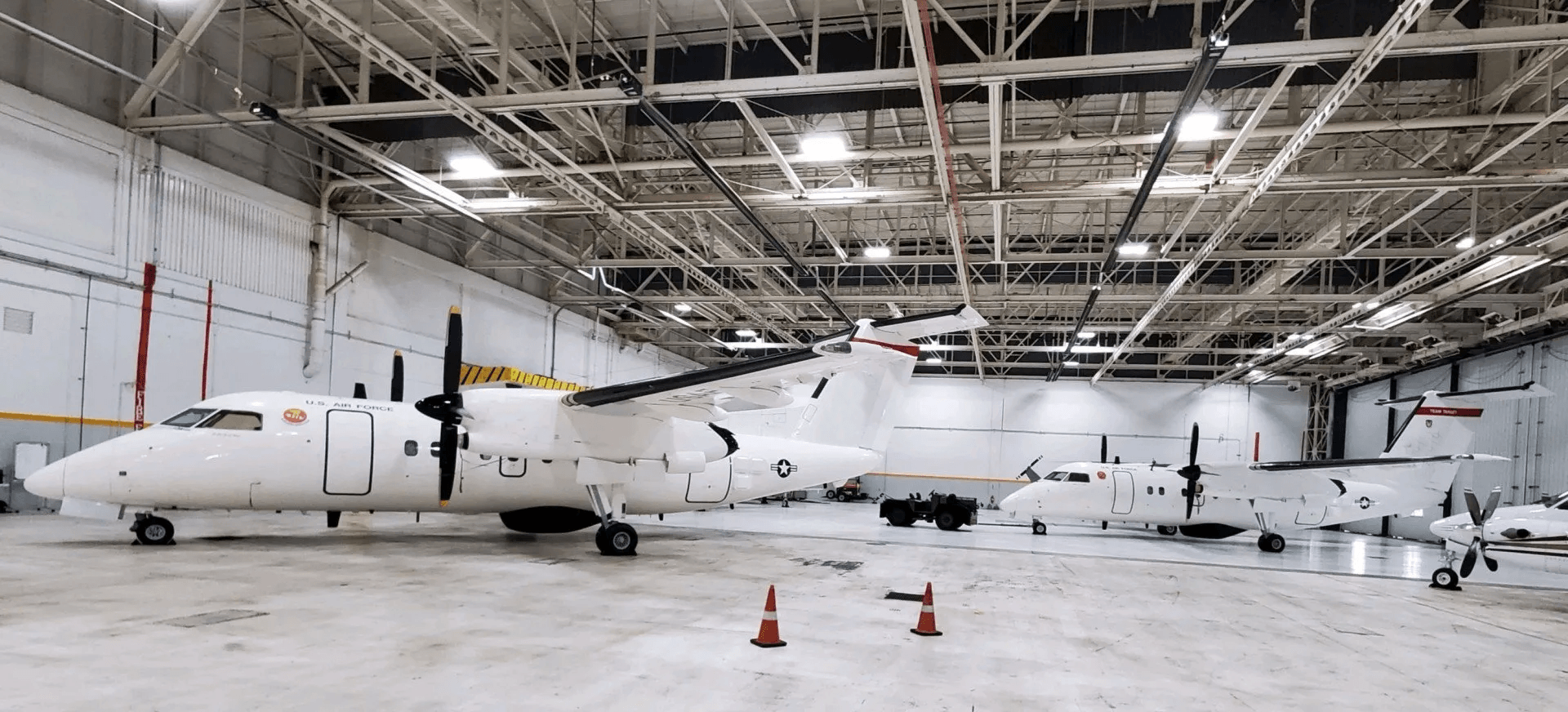

We provide aircraft parts receiving inspection, inventory, handling and shipping logistics processes operating as an FAA certified Repair Station in our hangar facilities in Columbus, Ohio. Our aircraft hangar facilities provide attached climate-controlled warehousing, wire harness and structural piece fabrication shops and dedicated, Electro-Static Discharge safe parts handling spaces.

Spirit Aeronautics utilizes Corridor as our internal Enterprise Resource Program managing every aspect of all kitting work orders generated in our business. This cloud-based Enterprise Resource Program provides the highest levels of capability and security for parts traceability and inventory management in the MRO industry. It is tightly integrated into our standard operating procedures to provide real-time work & parts status visibility ensuring smooth process transitions in a single, company-wide communication stream. All Spirit team members actively utilizing this tremendous resource provide exceptional value to our clients. With these efficiencies, we provide significant savings of costs in aircraft downtime and money due to our effectively managed business practices utilizing industry’s finest resources in logistic process and data management technology.

The aircraft modification kiting capabilities provided by Spirit Aeronautics offer excellent value. We ensure the highest quality standards are delivered by a team of very dedicated, safety minded aviation industry professionals.